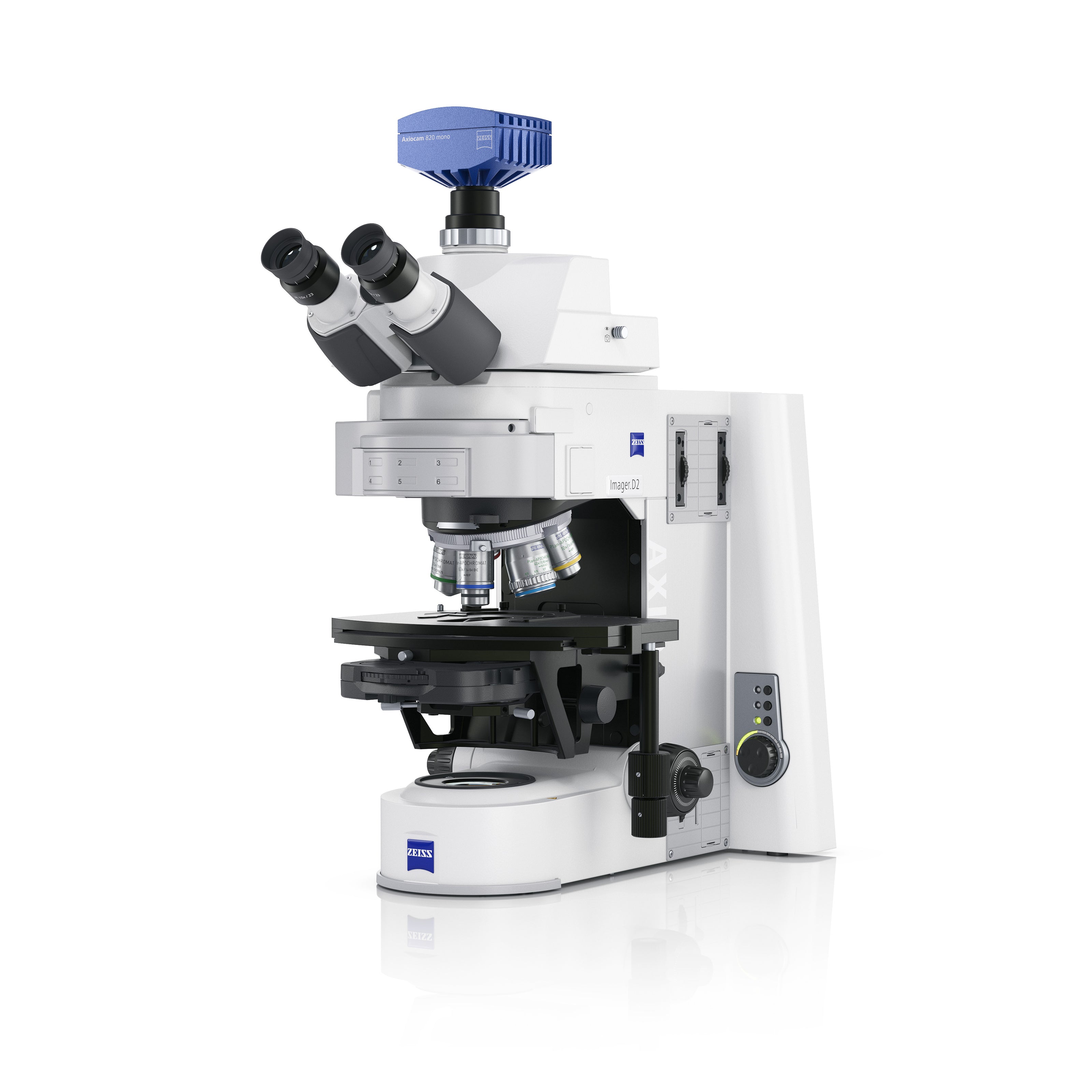

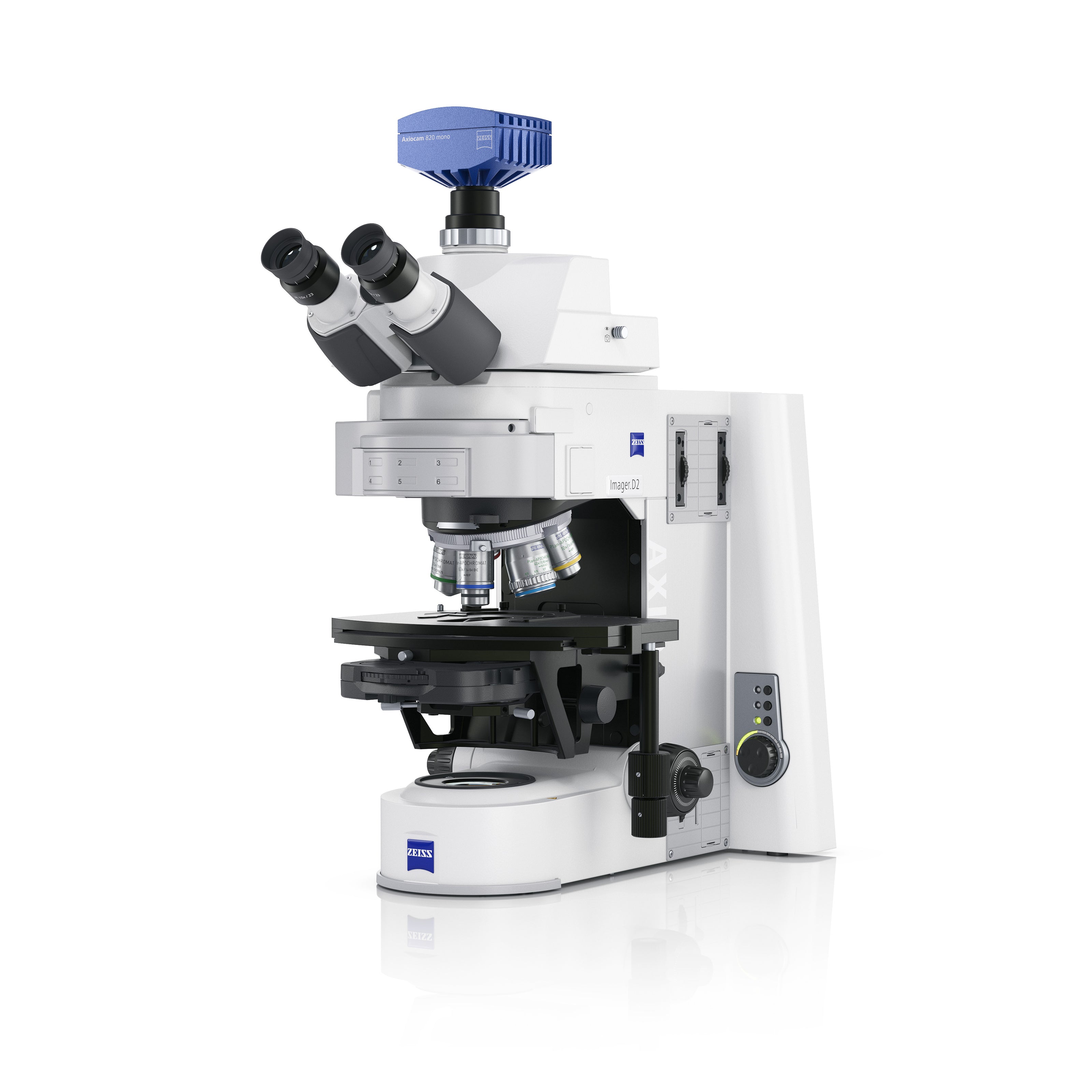

Axio Imager 2

PRECISION PLATFORM FOR MATERIALS INNOVATION

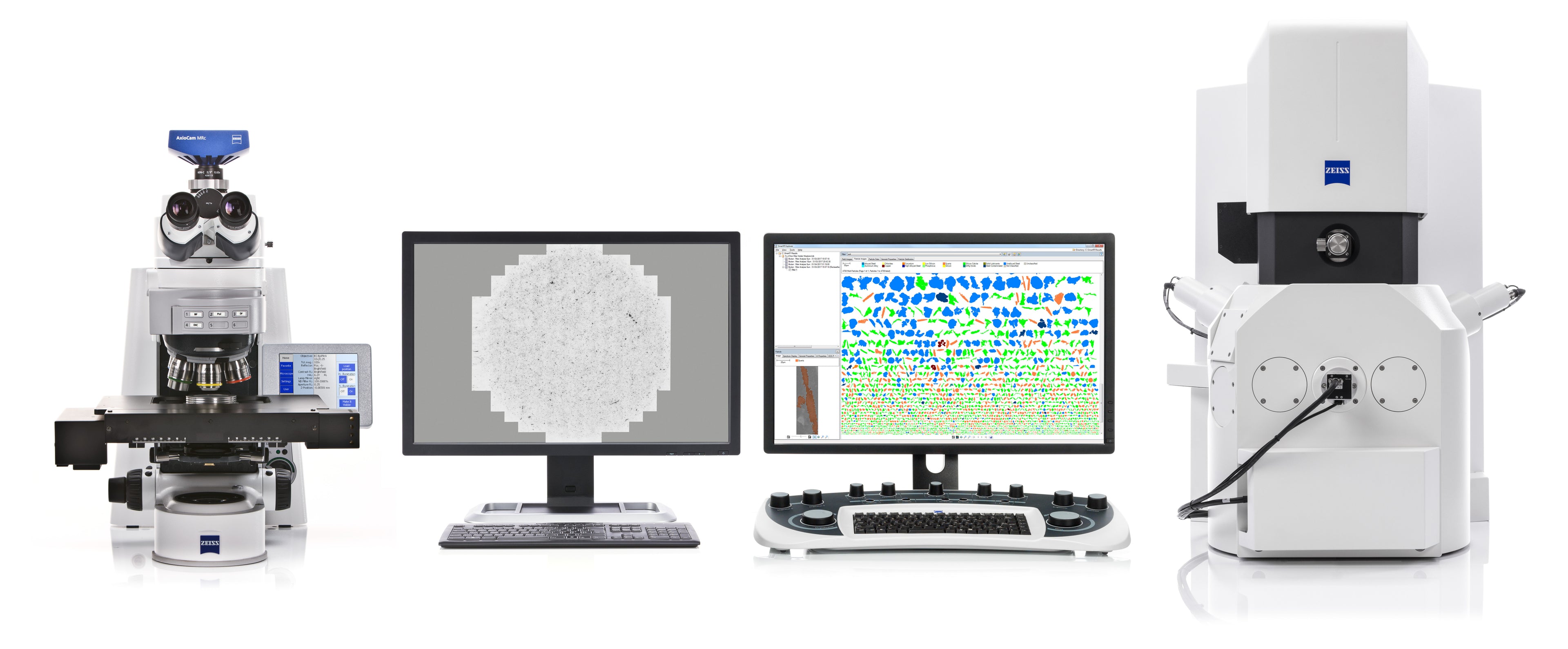

- Automated Imaging

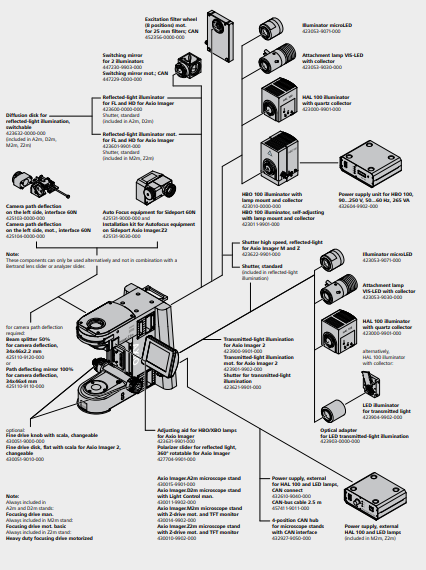

- Fully Modular

- Engineered for Materials Science

Axio Imager 2

-

Axio Imager.A2m

Manual Stand

- Coded Components

- Manual Focus

- Manual Stage

- Manual Light Path

-

Axio Imager.D2m

Motorized Light Path

- Coded Components

- Manual Focus

- Manual Stage

- Motorized Light Path

-

Axio Imager.M2m

Motorized Stand

- Coded Components

- Motorized Focus

- Motorized Stage

- Motorized Light Path

-

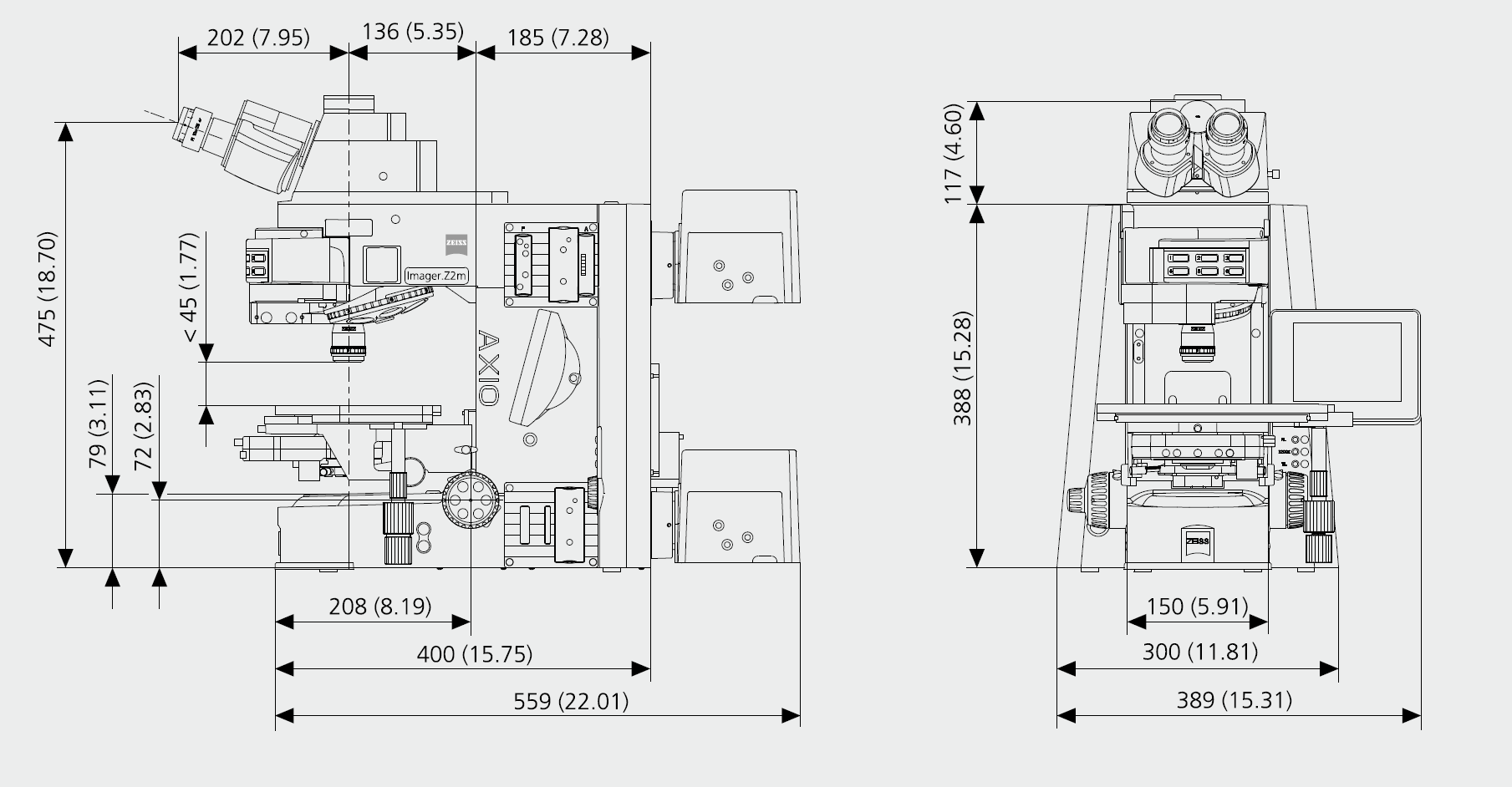

Axio Imager.Z2m

High Precision Motorized Stand

- Coded Components

- Motorized Focus

- Motorized Stage

- Motorized Light Path

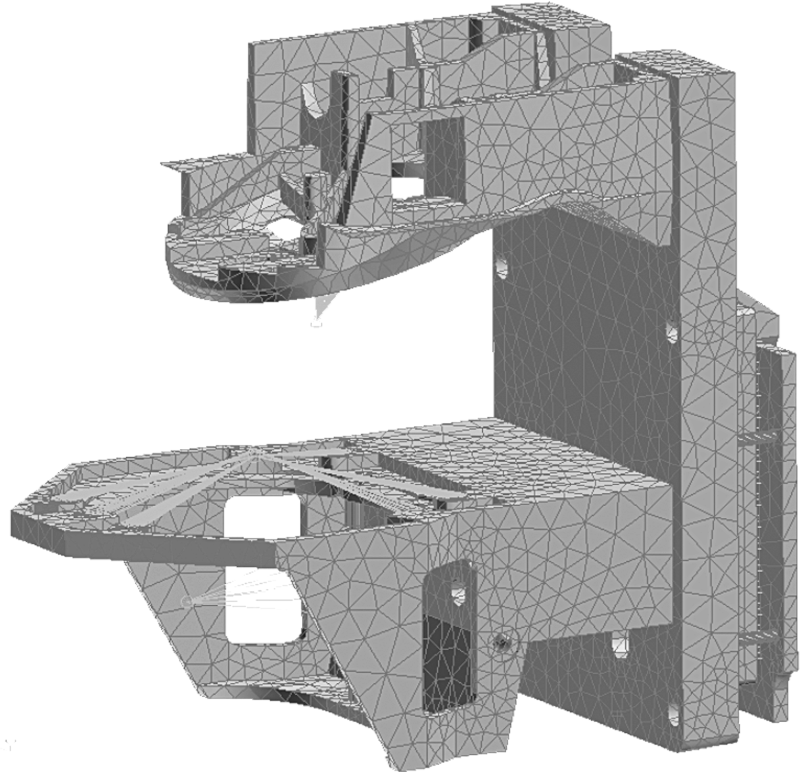

Undisturbed Stability at High Magnification

At magnifications where vibration, drift, and stray light ruin contrast, the Axio Imager retains stability. By motorizing key components, locking illumination paths, and optimizing mechanics, your images stay sharp — session after session — even in demanding industrial or multiuser labs.

Expand with Confidence

The future doesn’t need to be unpredictable. With a modular open architecture, the Axio Imager lets you add in particle analyzers, correlative-electron workflows, multipoint automation, and more. You’re not buying a static instrument — you’re investing in a system that evolves with your needs.

Contrast That Delivers Insight

Materials are complex. One method of illumination isn’t enough. Use reflected light (brightfield, darkfield, DIC, C-DIC, polarization) and transmitted light (brightfield, darkfield, polarization) in a consistent, repeatable way. The built-in “Contrast Manager” and motorized apertures ensure that what you see is what you measure — with minimal stray light.

Smarter Automation, Smarter Output

Set up automated routines — autofocus, stage scanning, imaging sequences — and let the system do the heavy lifting. Every image is captured with full metadata (scaling, illumination parameters, camera settings) so traceability and audit readiness happen without extra effort.

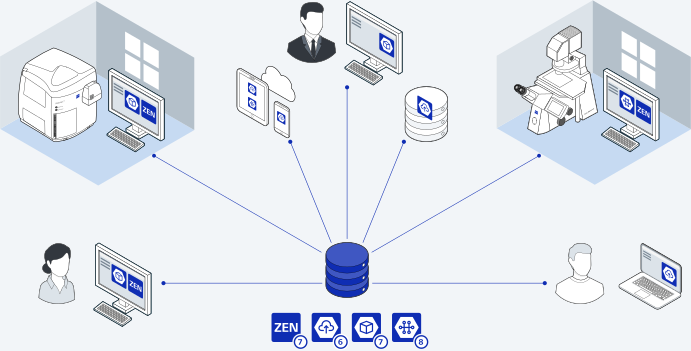

Connect your data with ZEN Core software

Designed for Materials Workflows

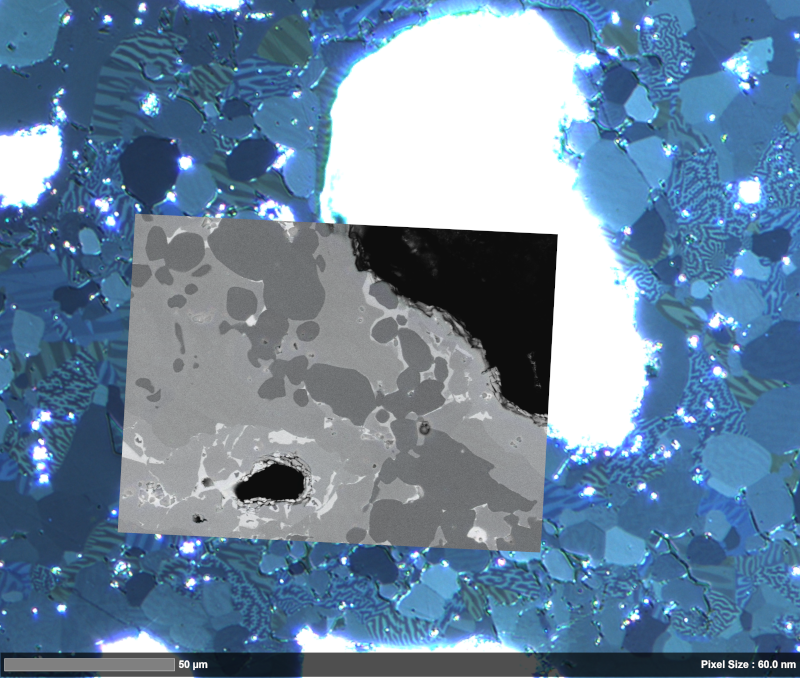

Correlative Microscopy Support — map light microscopy to electron microscopy and merge insights.

Materials Analysis — Grains Analysis, Layer Thickness, Porosity

Automation — Scan predefined regions of interest and conduct analysis

Thermomicroscopy — Heating and Cooling of samples over time

GxP — Data Integrity with Audit Trails

Downloads

-

Axio Imager

Product Brochure -

Axio Imager

Instruction Manual